The cockle stove

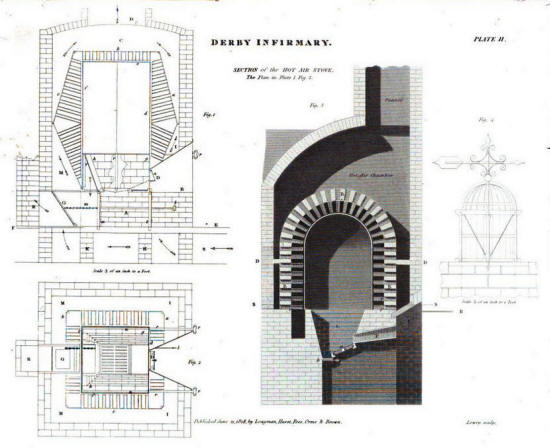

The cockle stove was originally designed to heat the large areas typically required in manufacturing processes such as drying sugar in a refining-house or for large buildings such as the Derby infirmary designed by William Strutt in 1810.

It was popular in such locations because, although the area to be heated was much larger than that to be found in any room in the average house (where wood or coal were usually burned in a fireplace), the air temperature required was little different from that needed in a house.

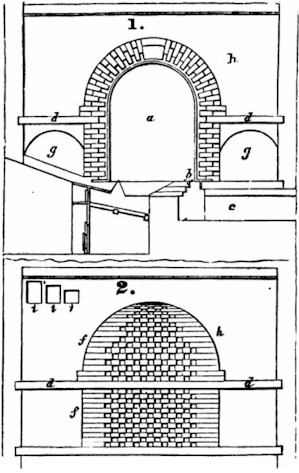

The cockle stove maximised the heat obtained by placing a large metal dome directly above an open furnace (a), the air being heated as it passed over the dome.

Fig.1 below is a section of the stove and cockle, and Fig.2 is a transverse section showing the brickwork surrounding the cockle, which is built inside an air chamber.1

The 3-4ft high cockle, had a cube-shaped lower part, with a dome or, more precisely, a groined arch top. It was made of plate or wrought iron about 3/16 of an inch thick, riveted together like a steam-engine boiler.

The air chamber was divided horizontally into two parts by a partition (d) which separated its lower and upper parts. The brickwork surrounding the cockle, and distanced about eight inches away from it, was built with alternate openings through which air could pass, shown in the side view at (f).

Fresh cold air from outside passed into the chamber through the main arched openings (g) and on through the lower brick casing into the space surrounding the cockle. As the air was heated it rose until it escaped through the brickwork into the upper part of the chamber. From here it was ducted into the hot rooms.

Immediately below the cockle was the fire, with its ash-tray shown to the left. The smoke, totally separated at all times from the air being heated, passed through a narrow passage (b) at the bottom of the cockle and along a flue (c), which led to the chimney.

Unfortunately, the harshness of the heat gradually destroyed the dome, and minute particles of metal were carried along with the airflow to be inhaled by the bathers. Another hazard was the ever-present danger of fire if the air flow was insufficient, and the dome overheated.

This page adds images to illustrate

the cockle stove,

mentioned on pages 89-90 of my book

Victorian Turkish Baths

VICTORIAN TURKISH BATHS

by Malcolm Shifrin

Published

2015

by Historic England

in partnership with Liverpool University Press

Distributed in the US by Oxford University Press

ISBN: 978-1-84802-230-0

Comments and queries are most welcome and can be sent to:

malcolm@victorianturkishbath.org

The right of Malcolm Shifrin to be identified as the author of this work

has been asserted by him

in accordance with the

Copyright, Designs and Patents Act 1988

© Malcolm Shifrin, 2015-2023